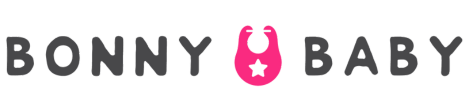

Hansfelds 0-6bar Pressure Gauge Liquid Filled1/2”BSP Lower Mount 100mm Dial Face stainless steel case Brass Connection Dual Scale bar/psi Accuracy 1.6

£20.15

Description

Price: £12.77 - £20.15

(as of Feb 08, 2025 08:03:37 UTC – Details)

Product Description

Add To Basket

Add To Basket

Customer Reviews

4.7 out of 5 stars

34

4.7 out of 5 stars

34

5.0 out of 5 stars

1

3.0 out of 5 stars

1

4.7 out of 5 stars

34

4.7 out of 5 stars

8

Price

— £15.75£15.75

—

— £20.15£20.15

—

Case Material

Stainless Steel Stainless Steel Black Metal Black Metal Stainless Steel Stainless Steel

Anti Corrosion

✓

✓

✓

✓

Anti Fog

✓

✓

✓

✓

Stable Pointer In Vibration

✓

✓

✓

✓

Brass Thread

✓

✓

✓

✓

✓

Waterproof Grade

IP67 IP67 IP67 IP67

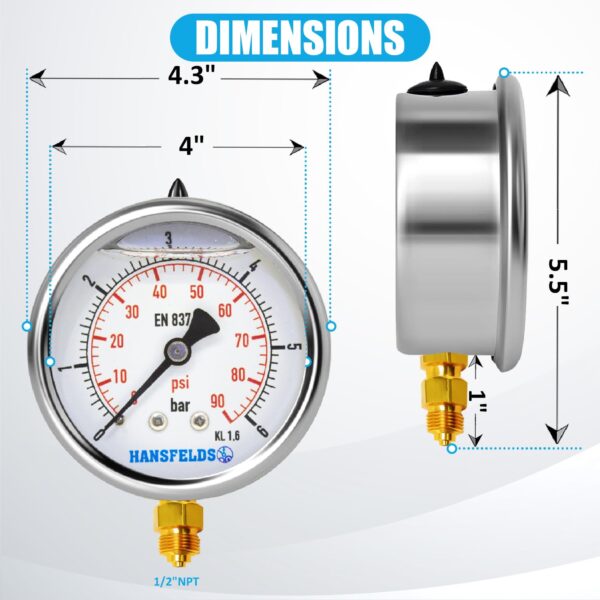

How to select the correct scale range?

Users should verify that they’ve chosen the suitable pressure gauge based on its scale range and design. The optimal choice for the scale range is when the operating pressure falls within the middle one-third of the scale range.

Why Opt for Liquid Filling?

Liquid filling serves to dampen vibrations, absorb mechanical shock, and mitigate pressure pulsations, making pressure readings more accessible. Liquid filling prevents corrosion, moisture ingress, and icing caused by the surrounding environment. Liquid filling also lubricates all moving parts, significantly decreasing wear and tear on the mechanism.

Where are pressure gauges with liquid filling applied?

Pressure washers and spraying devicesEquipment used for paint spraying and CompressorsIrrigation machineryHydraulic systemsHandheld hydraulic tools

Instructions for Venting a Pressure Gauge:

For pressure ranges up to 6 BAR, it’s important to provide gauges with some form of venting mechanism, such as a compensating membrane or vent valve. This is necessary to account for changes in pressure caused by variations in ambient temperature, such as direct sunlight, which could otherwise distort the pressure readings. (Gauges with pressure ranges exceeding 6 BAR do not require compensation, as the pressure inside the case is negligible in relation to the full scale range.)

All pressure gauges designed for liquid-filling are equipped with a device to ensure atmospheric compensation. To properly vent the solid rubber fill plugs, you can easily achieve this by trimming the tip of the plug, creating a small hole that allows the gauge to vent. This is necessary when mounting the gauge in an upright position.

Versatile Applications:Thanks to their multifunctional design, these pressure gauges are perfect for a variety of uses—from automotive to HVAC systems—making every project smoother than ever.

MULTI PURPOSE

ANTI FOG ANTI CORROSION STABLE POINTER

Anti-Fog :

Our pressure gauges are equipped with advanced anti-fog features, ensuring clear visibility of readings under various environmental conditions. This technology prevents condensation from forming on the dial face, providing you with accurate measurements at all times. Anti-Corrosion Protection: Designed for durability, our gauges feature anti-corrosion materials and finishes. This ensures long-lasting performance even in harsh environments, protecting against rust and wear over time. This resilience makes them ideal for industrial applications where exposure to moisture and corrosive substances is common.

Stable Pointer:

The stable pointer mechanism enhances the accuracy of readings by minimizing fluctuations caused by vibrations or sudden pressure changes. This feature ensures that you can rely on your pressure gauge for consistent and precise measurements, crucial for effective monitoring and control in various applications.

ANTI FOG ANTI CORROSION STABLE POINTER

Applications Used for hydraulic and pneumatic systems Compressors,compressed air system Suitable for fluid medium which does not clog connection port or brass Used for providing protection from vibration and pulsation.

Case, Ring:stainless steel Window:polycarbonate. Liquid:glycerine,silicone

Socket & Connection:brass Bourdon tube:copper alloy(brass) Pointer and dial: aluminum

Accuracy Class:F±3/2/3%(ASME B40.100 Grade B) Kl 2.5 FOR 1 1/2″,2”, Kl 1.6 FOR 2 1/2″,3″,4”

Operating temperature Ambient:-4°F to 140°F (-20℃ TO +60℃) Media:140°F (+60℃)

Related Products

BOMATA Large Kitchen Scale with 0.1g High Precision, Capacity 5kg, Bakery Scale with% Percentage Function, USB Rechargeable, Full-View Angle LCD with Backlight, Stainless Steel Pan

Brifit Digital Coffee Scale with Timer, 3Kg/0.1g Precision Espresso Scale, Rechargeable Multifunctional Food Scale with HD LED display, Touch Button, Tare Funtion, Temperature Resistant (g/ml/oz)

Digital Coffee Scale with Timer Rechargeable Coffee Scale, Temperature Resistant Kitchen Scales Food Scale Tare Function Precision Weight 0.1g-3000g, Units:g/oz/ml

Grundig Weight Scale – Weighing Scales for Body Weight up to 180 kg – Digital Bathroom Scales with Non-Slip Feet – Scale including Temperature Gauge – Bamboo

UNIWEIGH Food Kitchen Scale Bowl,Digital Gram and OZ for Cooking,Baking,Dieting,Weight Loss,with Removable Bowl 2.15L Volume, Room Temperature,Timer, Backlight LCD Display, Stainless Steel, 11lb/5kg

Venga! High precision Digital Kitchen Food Scale, weighs up to 5kg in steps of 1 g, Stainless Steel Cover, With Ambiance Temperature Sensor and Clock, Black/Stainless Steel, VG EKS 3000

At Bonnybaby.co.uk, we're committed to helping you find the best deals on baby products. Our goal is to make your shopping experience smooth and enjoyable by offering a wide range of products for your little one. From essentials such as diapers and baby food to toys, clothing, and nursery furniture, we provide everything you need for your growing family.

Our team carefully selects the top-selling products from Amazon and other trusted brands, prioritizing safety, quality, and value. We strive to offer you the best options at great prices so you can confidently shop for your baby's needs.

Thank you for choosing Bonnybaby.co.uk as your go-to source for baby products. We look forward to being a part of your parenting journey and helping you find the perfect products for your child. Feel free to reach out with any questions or feedback. Happy shopping!